White Papers

Advanced Analytics and Machine Learning: Its relevance to Refineries and Petrochemicals

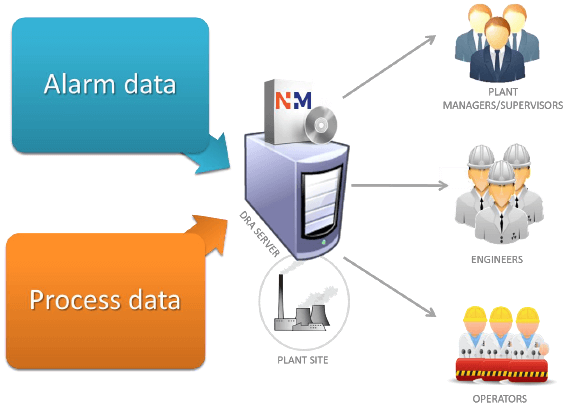

The refining industries have been evolving since the 19th century, with tremendously growing production capabilities and efficiency. However, never before have we utilized the vast amount of data that is generated by DCS, SCADA, and other systems daily to find hidden bottlenecks, optimize processes and predict failures. In this white paper, we will talk about this asset of data, the challenges it brings for process engineers and how advanced analytics can help solve those challenges in the refineries and petrochemical industries.

Using Big Data to Predict Process Risks

The team – plant manager, supervisors, and head operators - talk about the industrial fluid-catalytic-cracking-unit and the key question, “how did our catalyst standpipe do?” The answer: “not great, and we’re not sure why.” Plant management knows the regenerated catalyst standpipe is prone to disturbances, which leads to frustrating operational ‘hiccups’ (and trips) every now and then. It’s one of the most profitable units in the refinery, with a best-in-class historian as well as manufacturing intelligence software. The systems generate hundreds of thousands of data points. Yet, the magnitude of risks and reliability associated with the standpipe (and how they change dynamically) remain unknown, creating challenges in managing for optimum efficiency.

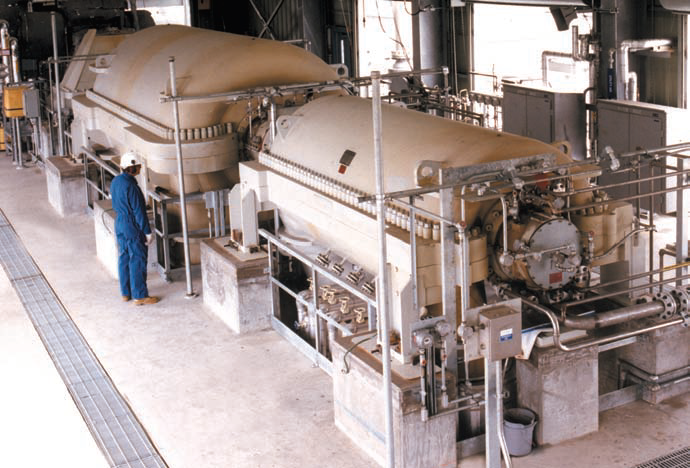

Optimize and Protect Cracked Gas Compressors with Smart Automation Technology

The cracked gas compressor is the single most critical piece of equipment in an ethylene plant. This asset can cost as much as $50 million and operates 24/7 under demanding conditions. Because it has no backup, ethylene producers know that if their cracked gas compressor trips – whether the trip was caused by excess vibration, a surge, an instrument malfunction or other problems – their entire process may be brought to a halt for up to a week.

Challenges, Opportunities, and Strategies for Integrating IIoT Sensors with Industrial Data Ecosystems

Today’s Industrial Internet of Things (IIoT) encompasses advances in sensor technologies, connectivity, analytics and cloud environments that will expand the impact of data on enterprise performance management. Recent market analysis predicts that lowered sensor cost, energy requirements and ease of connectivity will result in an explosion of industrial sensors and sensor-based data. For example, Cisco’s Internet Business Solutions Group predicts that by 2020, 50 billion IIoT devices will be deployed and active.