Challenges, Opportunities, and Strategies for Integrating IIoT Sensors with Industrial Data Ecosystems

Introduction

Today’s Industrial Internet of Things (IIoT) encompasses advances in sensor technologies, connectivity, analytics and cloud environments that will expand the impact of data on enterprise performance management. Recent market analysis predicts that lowered sensor cost, energy requirements and ease of connectivity will result in an explosion of industrial sensors and sensor-based data. For example, Cisco’s Internet Business Solutions Group predicts that by 2020, 50 billion IIoT devices will be deployed and active.

Today, one can find many subtle variations in IIoT definitions. For the purpose of this paper we will define IIoT as:

Definition:

The connection of digitally networked sensors and sensor-based data to visualization and analytics environments hosted in the cloud or on-premises. IIoT enriches existing data ecosystems to enhance decision support for actions influencing control, design, and service in industrial operations.

Collecting data and transmitting data from industrial machines and devices is not a new concept. Since the early ’80s, data from industrial assets has been captured, stored, visualized and analyzed to improve key business impacts such as asset health, resource conservation, and process efficiency. This paper explores the challenges, benefits, and strategy of adopting IIoT technologies to create a “hybrid” sensor-based data environment. Capturing information illuminated by IIoT sensors will enrich existing industrial sensor-based data ecosystems to transform operations, business models and the ways organizations communicate with customers, supply chain and business partners.

From Data to Transformational Impacts with IIoT

In B2C markets, embedded technology is enabling manufacturers to assess device usage patterns, upgrade products remotely and offer additional aftermarket services. In B2B or industrial settings, IIoT offers the opportunity to connect operators, engineers, and managers to a richer data landscape in order to improve operational visibility and sharpen operational insight. Areas in which IIoT data can typically generate value include:

ASSET PERFORMANCE MANAGEMENT Through either remote or on-premises monitoring, sensor data supplementing existing operational sensor-based data ecosystems can enhance real-time situational awareness, close information gaps and operationalize assets that were previously unmonitored or monitored manually. IIoT broadens the scope of asset data sources to heighten texture and resolution of existing information. Industries can use the information to streamline maintenance costs, improve process efficiency and increase asset availability.

IMPROVED PLANNING & PRODUCTIVITY IIoT enables industries to monitor the physical state or location of people as well as mobile or geographically dispersed assets. When combined with the process or asset data, industries can operationalize data sources that surround core industrial machinery to enhance safety, field force and operational efficiencies.

DATA-DRIVEN COMMUNICATION WITH CUSTOMERS, PARTNERS, AND COMMUNITIES IIoT sensors and devices produce data and information relevant to broader ecosystems. Sharing data across these ecosystems will transform communication between customers, businesses and across larger ecosystems. Secure data exchange across these broader data environments will create new business models and associated revenue streams through opportunities such as expanded service offerings, establishing data-driven collaboration and partnerships.

Learning from the Past

As industries transitioned from analog and pneumatic controls to digitalized PLCs and SCADA, they have leveraged sensor-based data to optimize control and design of their assets and processes – both in real-time and overtime.

Fundamentally, IIoT does not change the value of data within industrial and community ecosystems. Rather, it complements the value of existing data. In the near term, IIoT data can close information gaps, increase the resolution of sensor-based information and create data-driven communication across traditional organizational, security and geographic boundaries. As machinery with embedded sensor technology is incorporated into enterprise value chains, IIoT will increasingly enable auto-regulated, intelligent operations at the local, plant, enterprise and supply chain levels.

For now and for most industries, however, a full-scale IIoT approach to industrial data capture, integration, and storage to drive enterprise performance is neither practical nor cost-effective. The reality of today’s industrial world is that technology is already in place to monitor many mission-critical machines and key operational processes. While newer, “smart” machines may include embedded sensors, it is more cost-effective to extend the lifecycle of existing assets using existing technologies. Deriving value from IIoT will more likely mean finding ways to capture and store data from new technologies, sources and open networks and integrate this with pre-existing sensor-based data systems.

The Challenge Ahead

As industrial sensors and devices create hybrid data environments, IIoT will propagate more data from more locations, in more formats and from more systems than ever before. Data management and governance challenges that have pervaded operations for decades will become a more pressing reality of the future. Strategies to manage the volume and variety of IIoT data need to be administered now to harness the opportunity IIoT promises.

The following themes will present challenges to utilizing sensor-based data to create information that is actionable, predictive and relevant to core operations:

Multiple Protocols

Multiple Protocols

As the number of devices and sensors grows, increases in the number of data acquisition “protocols” are creating a greater (not lesser) need for new “interfaces” for device networking and integration with existing data ecosystems.

Bigger Data

The sheer volume and dynamic nature of IIoT can exceed the capacities of systems used to generate actionable information for operational decision support. Sensor and sensor-based data will need to be cleansed, aggregated, aligned and transformed to be “decision-ready.”

Data Variety

As sensors and devices are deployed to fill information gaps and operationalize assets outside of traditional enterprise boundaries, centralized data management systems must be able to integrate disparate data types and additional context dimensions to create a unified view of operations and how it aligns with business objectives.

New Data Silos

Purpose-built systems produce data silos that create barriers to using data for multiple purposes and by multiple stakeholders. Without foresight, IIoT “solutions” represent the new silo – undermining the intent to construct architectures that incorporate IIoT to build broader, interactive data ecosystems.

New Devices & Sensors

Unlike other industrial sensors, new edge devices and sensors may be expendable, not “high quality” and/or change locations. Concentrators, aggregators, gateways, head-end systems are needed to aid in the lifecycle management of broadly deployed sensors and devices. Maintaining an accurate, consistent data footprint will require coordination from multiple vendors, customers, and perhaps third-party service providers.

Context and Community

Unlike sensors in traditional PLC, DCS, and SCADA, IIoT sensors can be geo-dispersed with no inherent physical locus. To capture the richness of information illuminated by IIoT sensors, multiple technologies will be required to link sensor data with real-time operational context. Also, data generated by a single sensor may be useful to multiple parties. Several “contextual views” may be needed to enable multiple applications, scenarios, and services.

To overcome these challenges, partnerships between vendors, customers and service providers will be required build systems to capture, integrate and distribute IIoT and sensor-based industrial data in a way that aligns with business objectives and creates revenue-bearing deliverables.

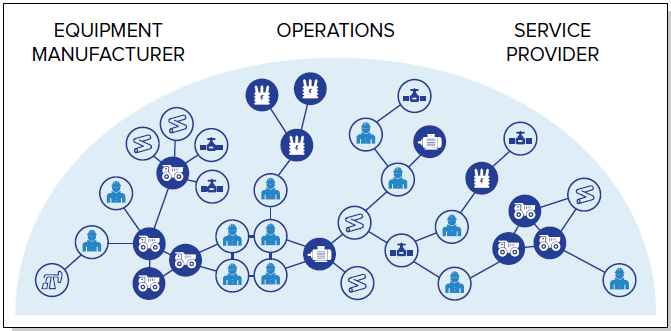

The Ecosystem Opportunity

IIoT supports the data needs of expanded operational communities and novel business models that traverse traditional enterprise fence lines.

- OPERATIONS PERSONNEL IIoT enables a feasible, cost-effective solution to enrich existing operational data ecosystems. Traditional control systems, like SCADA, can be inherently difficult and expensive to upgrade or extend. IIoT sensors can supplement existing operational data sets to improve overall situational awareness and focus decision support. In some operational settings, traditional process and control systems may not be present because assets are remote or geographically dispersed. IIoT makes it possible to monitor structures, equipment, and environments to operational assets in these remote regions where previously it was neither possible nor cost-effective. Merging IIoT data sources with traditional operational technologies makes IIoT data actionable by making it durable and integrated with larger operational contexts.

- EQUIPMENT MANUFACTURERS For industrial equipment vendors, IIoT offers an opportunity to improve customer relations through value-added services. Advances in technology allow for a more robust, cost-effective means to connect data from embedded sensor technology to subject matter experts and design teams. With access to real-time data from their products, equipment vendors can make recommendations with respect to maintenance, use, and operations. Customers can increase equipment availability, reduce total cost of ownership and avoid failures. IIoT connectivity means that equipment vendors can offer services that increase brand equity and improve customer retention and future product design.

- INDUSTRIAL SERVICE PROVIDERS deliver services to support efficient and compliant operations at remote customer sites. IIoT offers an affordable way for service providers to monitor assets and systems in their customers’ environments. Service providers embracing IIoT and remote monitoring can gain a competitive edge through ongoing, real-time visibility into customer operations, gaining customer trust and reducing time-to-solution. These data-driven “connected services” also lower costs passed on to customers by improving field force efficiency, protecting and improving the intellectual property and scaling to match growth – both in expertise and market.

Strategy to Embrace IIoT and Existing Investments

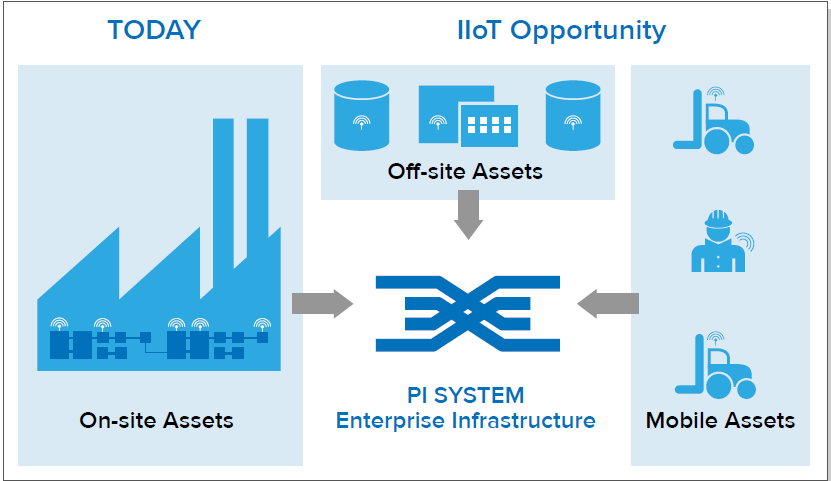

For over 30 years, OSIsoft customers have used the PI System™ to overcome challenges, such as fragmented data records, siloed information and “multiple versions of the truth.” If implemented without foresight and planning, IIoT promises to replicate and even further aggravate these challenges. The PI System enables industries to take an infrastructure approach to data management. It integrates disparate data sources, multiple protocols, and information silos to create a single, comprehensible source of data so people throughout the enterprise can create actionable information, knowledge, and intelligence.

As industries look for ways to build business value with IIoT sensor data, a PI System infrastructure can serve as the backbone to integrate new sources of sensor data with core information systems. This strategic approach provides the framework to embrace IIoT by optimizing enterprise data governance and accessibility as well as ensuring the IIoT data can be woven into existing information systems.

As businesses strive to use IIoT data to operationalize new parts of the enterprise, a first step forward includes connecting and organizing all existing sources of operational data using an infrastructure approach. As IIoT data sources that deliver business value are identified, teams can build upon a PI System infrastructure to encompass and add operational context to newer sensor-based data sources. In essence, extending the PI System to embrace new IIoT opportunity offers to connect IIoT sensor data from geo dispersed assets and personnel to core operations and at the same time mitigate the challenges associated with diverse, mobile data sources.

Summary

For over 30 years, industries have been leveraging sensor-based data to gain visibility into operations, support continuous improvement and generate information to optimize overall enterprise performance. As advances in technology make it more cost-effective to deploy IIoT, industries will need to develop a strategic approach to integrating IIoT sensor data with pre-existing data environments. Creating a seamless, extensible data ecosystem will require cooperation between multiple vendors, partners, and system integrators.

As IIoT continues to evolve, OSIsoft and its extended Partner Ecosphere are working to advance the PI System to support change, enabling our customers and partners to embrace IIoT opportunities in a continued, scalable and persistent manner.