Rotating Equipment Reliability improvement by predicting time to failure.

About Customer

- Customer is a Client of ATEK, one of the leading Industrial IIoT Solutions vendor, They provide IIoT sensors to access “Asset Health” to improve Reliability and Safety of critical equipment.

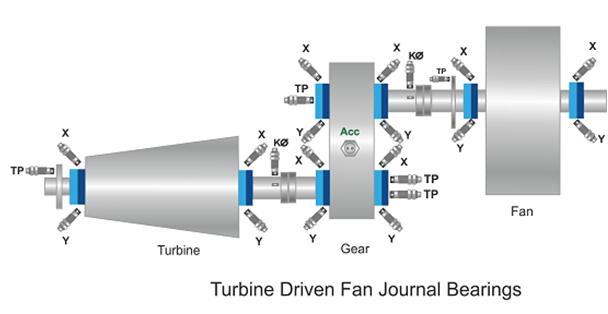

- Typical application includes rotating equipment like Compressors, Turbines, Motors, Fans, Pumps etc., using their AssetScan range of products.

Objective / Challenges

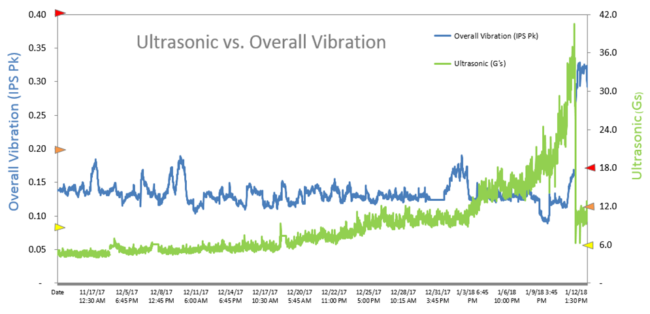

- AssetScan readings instinctively alerts the client Qualitatively with range of vibration data about Actual Conditions about “Acceptable”, “Suspect” & “Alarming”.

- However, customer wants to predict the failure of a fan bearing based on the Asset Scan vibration data.

- Objective was to predict days to failure dynamically, so that inventory & maintenance planning can be done proactively.

Solution to problem

- Regressive models like Gradient Boosted Trees, ARMA etc., have been tried but, of limited usefulness or Predictive Power.

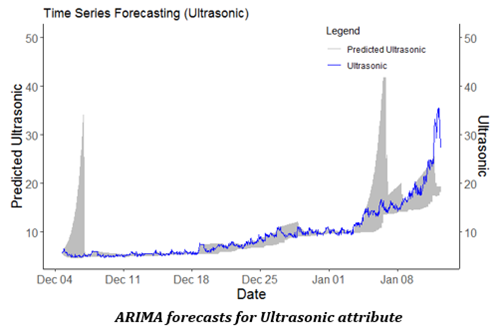

- Autoregressive Integrated Moving Average (ARIMA) model with unique Feature Engineering helped to forecast the time series accurately.

Feature Engineering:

- Delta: Feature captures detrended dependencies of our original attributes.

- Days of operation: Attribute calculates day of operation since last maintenance. It helps to factor in the age of current trend.

- Days to failure: This feature was created by our domain experts to suggest the remaining days of safe operation.

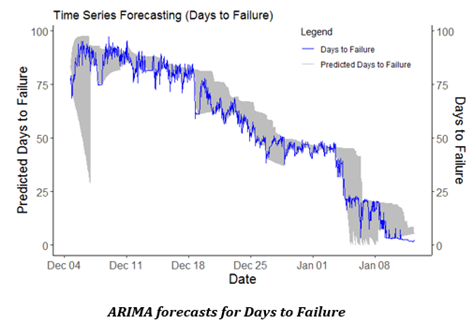

Time Series Forecasting:

- ARIMA model used is able to predict values of ultrasonic vibrations for next 2 days in advance based on previously observed values.

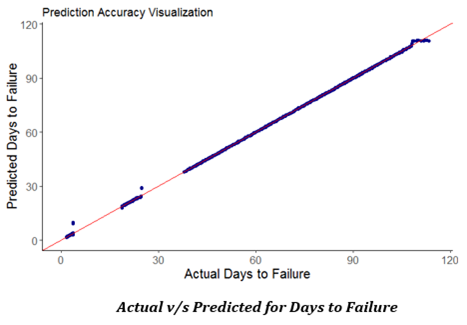

- Forecasting models help to predict time of failure dynamically using real-time data, i.e 60+days in advance. with predictive accuracy of 95% .

Benefits realized

- Though Condition Monitoring devices like Asset scan range of IIoT devices help to decipher asset health at a given point qualitatively;

- Given 100s of Rotating Equipment in any given CPI facility, predictive models with GUIs can help operational team to be better equipped for:

- spare parts inventory management

- helps to anticipate failures, and plan type of maintenance in advance.

- planning for scheduled maintenance or turn around

- operations to have the real-time feel of their asset’s health