Remote Monitoring of Ammonium Nitrate Plant Facilities.

About Customer

- One of the leading Ammonium Nitrate manufacturers in Asia, producing 500,000 MT per year at three manufacturing plants geographically spread across.

- By virtue of higher personal safety concerns, onsite personnel is to be minimized.

- In the past, experienced few near-miss accidents due to inadequate monitoring & controls.

- The facility is of old school control systems & automation.

- The process is highly demanding in terms of narrow operational windows in terms of :

- Humidity Control.

- pH and Temperature Control.

- Dust & Particulate Control.

Objective of Remote monitoring is to:

- Provide Realtime monitoring, timely alerts, and process insights.

- Minimize deviations in process parameters to reduce process hazards.

- Optimize utility systems to meet the demands of multi-products batch operations with varying production throughputs.

- Optimize fuel and energy consumptions process equipment.

"Prognostic & Diagnostic monitoring has helped the facility to bring down near-miss incidents, improve safety records and energy consumption."

Solution:

Plant Systems Monitored Remotely.

- Process Unit HVAC systems.

- Boiler & Steam Systems.

- Cooling Water System.

- Dust Control in Coating, Loading & Bagging.

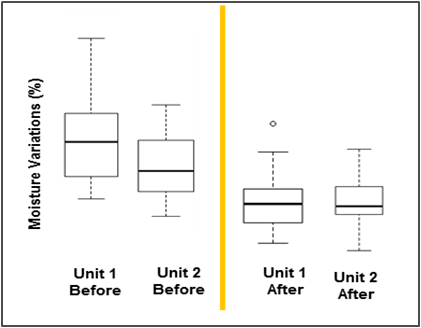

Improved Humidity controls with online monitoring.

Benefits:

- Breakthrough benefits in terms of safety & energy improvements are:

- Humidity & Process Temperature Control are of paramount importance in Explosives manufacturing.

- Humidity variations reduced from 60+ 15% to 60+ 5% variations.

- Process Temperature variability reduced from 110oC+ 15oC to 110oC + 5oC.

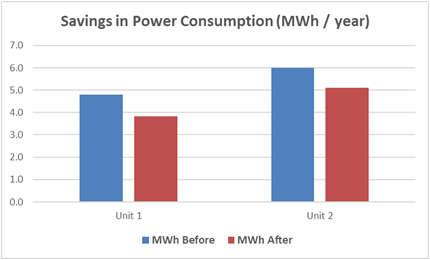

- Power Optimizations to the tune of 500,000 USD per year across:

- Cooling tower Fan & Pump running hours rationalizations.

- Fabric Filter system Airflow & Cleaning frequency optimizations.

- Boiler Management Controls (BMC) optimizations.

- Humidity & Process Temperature Control are of paramount importance in Explosives manufacturing.

- Visualization of current operating values in both text and graphic form to ensures there is a comprehensive overview of processing assets.

Reduction in power usage with online monitoring.